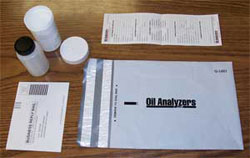

Oil Analysis Kits

AMSOIL provides oil analysis service options. By analyzing used engine oil, a qualified lab can detect mechanical problems your engine may have.

Product Code: KIT101 •

Brand: AMSOIL

Product Details

Reviews & Rating

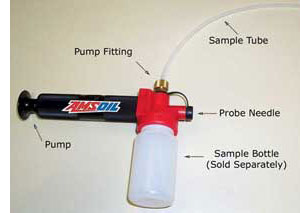

The Sampling Process Trend Analysis

Machines of the same type will accumulate contaminants and wear at different rates. Performing trend analysis on each machine is the most effective method of giving you an internal look at your equipment and enabling you to deal with developing problems before they become catastrophic situations. Sampling Frequency Collecting a clean and representative oil sample is critical to the oil analysis process. Put simply, an oil analysis is only as good as the sample taken. The accuracy and reliability of the data produced by an analysis hinges on receiving a representative sample from the equipment to be tested. To assure that the sample extracted is representative of the system, always follow proper sampling procedures. See more info at: http://www.oaitesting.com/ |

|

| 3 Easy ways to place your order now! | ||

|

|

|

Copyright © 2025 www.wboil.com. All Rights Reserved

Home | Privacy Policy | Site Map

A single sampling

analysis is useful in providing information when critical

failure conditions exist. However, trend analysis is a

better tool for estimating the useful life or overall

condition of your engine or equipment. Trend analysis

samples are taken and analyzed at regularly scheduled

intervals. Comparing the most recent analysis to previous

reports on a given machine shows the development of trends.

Monitoring these trends enables early detection of internal

abnormalities. Tested values falling within acceptable

limits may show a pattern of subtle variance, which could

signal a developing problem.

A single sampling

analysis is useful in providing information when critical

failure conditions exist. However, trend analysis is a

better tool for estimating the useful life or overall

condition of your engine or equipment. Trend analysis

samples are taken and analyzed at regularly scheduled

intervals. Comparing the most recent analysis to previous

reports on a given machine shows the development of trends.

Monitoring these trends enables early detection of internal

abnormalities. Tested values falling within acceptable

limits may show a pattern of subtle variance, which could

signal a developing problem.

Canada

Canada United States

United States